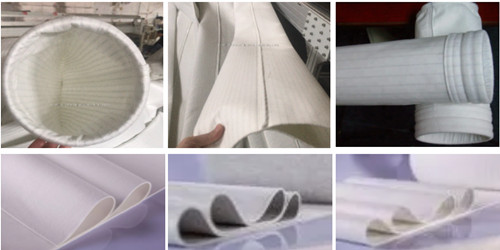

Polyester Dust Collector Filter Bag

Description of Polyester dust collector Filter bag:

Polyester needle felt is made from polyester fabric by needle punch, and treat with singeing,

calendering ,heat-setting process.This material has good friction resistance, high porosity,

good twist resistance, good air permeability. It is a kind of wildly applied normal temperature

needle felt .

Our capacity: 20,000 per month (standard product)

Size: Customization Accepted

Optional process: Sewing or hot welding

Filtration precision: ≤30mg/m³ (laminating PTFE film, ≤5mg/m³)

Finish-treatment: Calendering, Heat setting, Singeing

Optional Choice: Pleated Dust Filter Bag (Star Bag) and the main advantages and features:

1. To increase system filtration capacity by 50-150% as needed without major changes to the dust

collectors ;

2. System cleaning efficiency markedly increased with the effective increase of bag to bag distance;

3. Bag life extended due to significant reduction of fatigue damage to the bags due to bag to cage

impact

Kinds of filter bag paramenters:

|

Fiber Composition

|

Polyester

|

Polyester (PET) with

PTFE membrane |

PTFE

|

|

PPS

|

Nomex

|

|

Weight (g/m2)

|

500

|

500

|

750-800

|

500

|

500-550

|

450-600

|

|

Thickness (mm)

|

1.7-2.0

|

1.7-2.0

|

1.2-1.6

|

2.1

|

1.8-2.0

|

1.9-2.4

|

|

Running Temperature (°C)

|

130

|

130

|

240

|

180

|

160

|

200

|

|

Peak Temperature (°C)

|

150

|

150

|

260

|

260

|

190

|

240

|

|

Air Permeability

(M3/M2.S. 200Pa) |

8-12

|

8-12

|

5-8

|

14

|

15

|

8-12

|

|

Mechanical Finish

|

Singeing, calendaring,

heat-set |

Singeing,calendaring

|

Heat-set and

Singed one side |

Singeing

|

Singring

coating

Heat-set

|

Singeing |

|

Chemical Finish

|

membrane

|

PTFE/Teflon

coated

anti-static

Water and oil repellent

|

PTFE impregnated

peritoneal |

|

|

PTFE coating,

membrane |

|

Warp Of Stretch Strength

|

800

|

1000

|

600

|

900

|

900

|

900

|

|

Welf Of Stretch Strength

|

1200

|

1300

|

800

|

1200

|

1200

|

1200

|

|

Resistance to Acid

|

Medial

|

Fair

|

Excellent

|

Excellen

|

Excellent

|

Fair

|

|

Resistance to Oxidation

|

Excellent

|

Good

|

Excellent

|

Excellent

|

Poor

|

Fair

|

|

Resistance to Alkali

|

Medial

|

Poor

|

Excellent

|

Excellent

|

Excellent

|

Good

|

|

Resistance to Hydrolysis

|

Medial

|

Poor

|

Excellent

|

Excellent

|

Excellent

|

Fair

|

|

Application

|

1) The fume and smoke treatment and particle removing system in metallurgy plant

2) Smoke filtration in garbage burning, coal-feed boiler,power plant3) Asphalt concrete mixture, cements, chemical,ceramics, building materials

4) Dust treatment, purification and collection in electronics, mining, flour and timber processing

|

|||||

|

Size

|

Φ4'' ; 5'' ; 5.25'' 6'' ; 6.62'' Length: 18'' up to 192''

|

|||||

|

Filter Bag Top Construction

|

1) Side Load: raw edge top (3” longer than split collar cage length)

2) Top Load: snap band/ring ; double beaded |

|||||

|

Bottom Construction

|

1) Single-ply felted disc bottom

2) 3” bottom; double-ply wearguard

3) 5” wear cuff with 2” overhang below bag disc bottomBottom Construction

|

|||||

Packing details: polyester filter bag is packed in the weaving bag, 40pcs/bag.

Main Category

Popular Articles

Contact Us

Wechat: +86-15931082037

Whatsapp

Whatsapp